Gallery

Furniture by Anthony Balzar

Walnut Burl & Satinwood Table w/hand carving

Walnut burl table top w/satinwood short grain border

Carved walnut foot and burl veneer

Walnut burl leg with carved detail

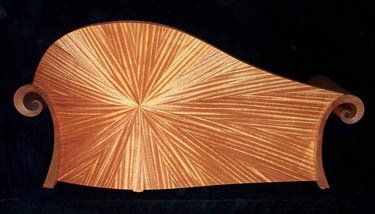

Mahogany crotch radial matched table

Mahogany crotch radial matched table

Mahogany crotch radial matched table top

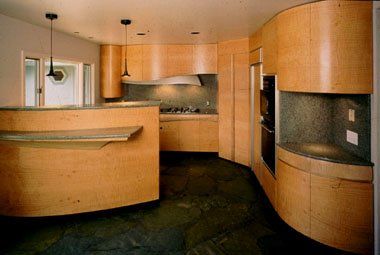

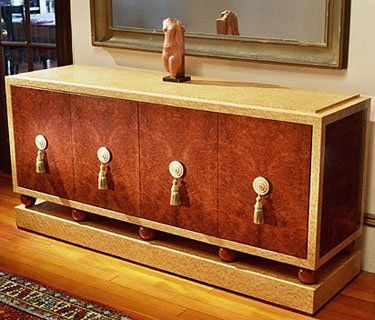

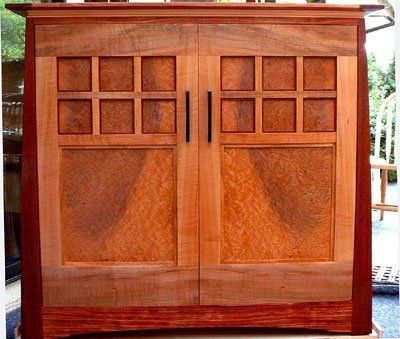

Furniture by Ferro Legno

Sideboard Bird's Eye Maple and Eucalyptus Burl with Sycamore escutcheons. 72" long, 20" deep, 34.5" tall.

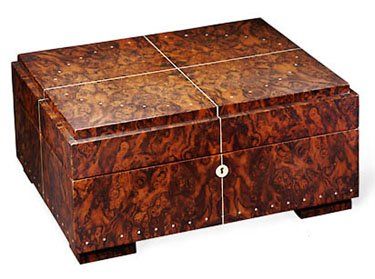

Jewelry Box 13"x17"x6" Walnut burl, mother of pearl and holly

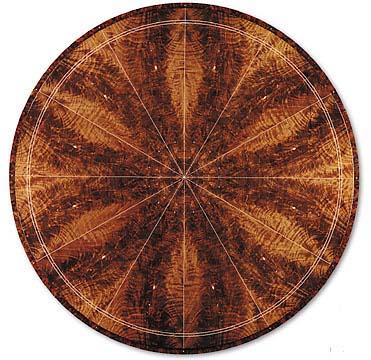

Walnut crotch and walnut burl, holly inlay, buffalo horn, and Okinawan sea snail. 72" diameter.

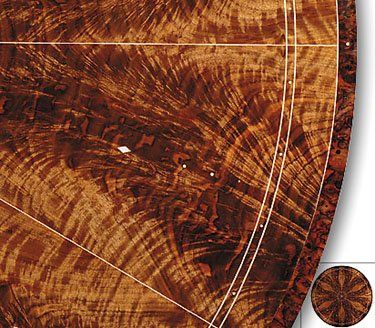

Detail of walnut crotch and burl, holly inlay, buffalo horn, and Okinawan sea snail.

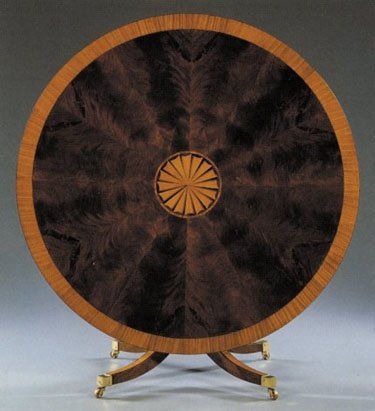

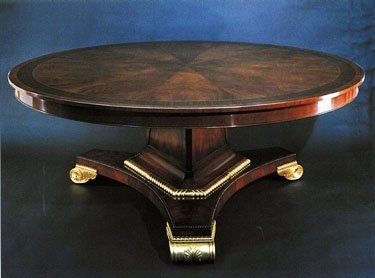

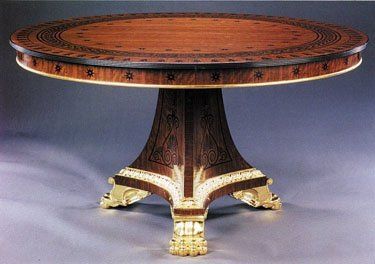

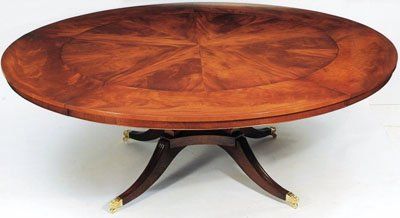

Tables by Craig Tufankjian

Walnut crotch with Premavera border and Premavera inlay with black dyed Costello

Crotch Mahogany with ribbon striped Sapele border and custom made brass cast fittings

Ribbon striped Sapele center with black dyed Costello border and inlays with brass cast fittings

Crotch mahogany with solid African mahogany base. Custom made circular extending leaf system

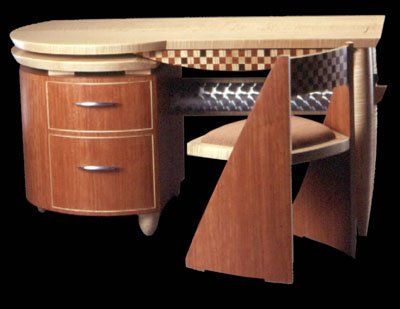

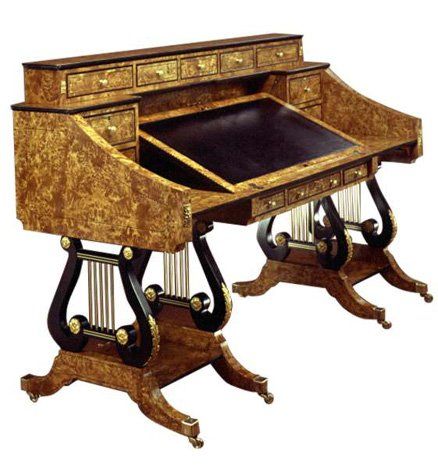

Furniture by Steve Holman

bubinga veneers and solids, figured maple, cocobolo, aluminum 60"l x 32"d x 30"h

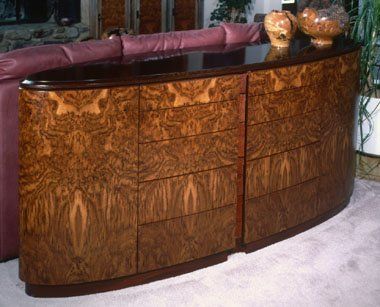

mappa burl veneers, maple, ebonized maple, ebony, brass, leather, gold leaf 72"l x 42"h x 30"w

Chen chen veneers, padauk veneers and solids, white oak, mahogany, bending plywood, aluminum; 29" high x 64" round.

Swirl mahogany veneers, mahogany veneers and solids, ebonized mahogany; 16" deep x 32" wide x 66" high.

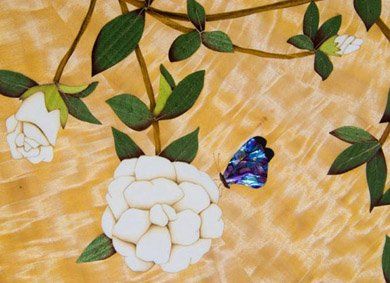

Furniture by Craig Thibodeau

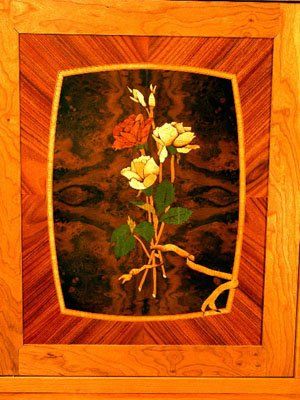

Gardenea Sideboard Wenge, Block Figured Anigre, Quarter Sawn Maple, Ebony, Pau Ferro, Boxwood, Maple, Poplar, Holly, and Anigre

Gardenea Sideboard Wenge, Block Figured Anigre, Quarter Sawn Maple, Ebony, Pau Ferro, Boxwood, Maple, Poplar, Holly, and Anigre

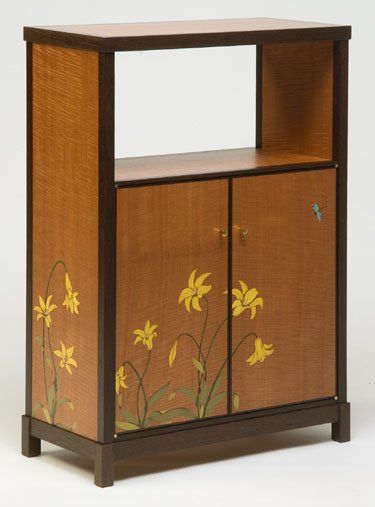

Lily Cabinet Wenge, Vavona, Honduran Mahogany, Dyed Poplar, Mother Of Pearl, Abalone, and Ebony

Lily Cabinet detail Wenge, Vavona, Honduran Mahogany, Dyed Poplar, Mother Of Pearl, Abalone, and Ebony

Chess Table Macassar Ebony, Holly, Bubinga, Ebony, Mother of Pearl, and Jatoba

Lily Table Wenge, Curly Anigre, Holly, Ebony, Dyed Poplar, and Mother of Pearl

Slate Desk Myrtle Burl and Maple

Campion Table Pau Ferro, Figured Satinwood, Holly, Ebony, Poplar, Dyed Poplar, Silver, and Aluminum

Campion Table Detail Pau Ferro, Figured Satinwood, Holly, Ebony, Poplar, Dyed Poplar, Silver and Aluminum

Slate Bench Myrtle Burl and Silk Fabric

Furniture by Joe Morgan

Demilune Table "End of My Rope" Walnut, Mahogany, Koa, Maple, Beach, Holy, Ipe, Black Dyed Veneer

Demilune Table "End of My Rope" Walnut, Mahogany, Koa, Maple, Beach, Holy, Ipe, Black Dyed Veneer

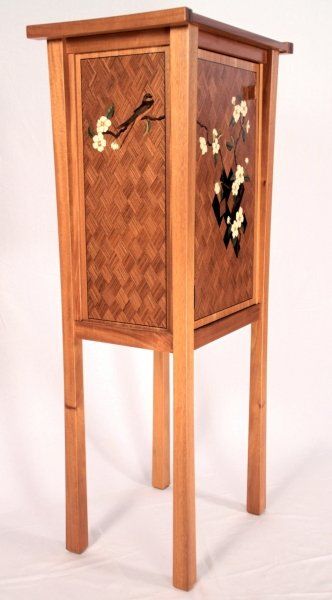

Cabinet "Opportunist" Mahogany, Jatoba, White Ash, Various Marquetry Woods

Cabinet "Opportunist" Mahogany, Jatoba, White Ash, Various Marquetry Woods

Cabinet "Opportunist" Mahogany, Jatoba, White Ash, Various Marquetry Woods

Compact 300 Vacupress® Pump (3cfm)

The Compact 300 VacuPress® Pump model is specifically designed for the small or home workshop. The Compact 300 is the perfect choice for woodworkers who want to explore the exciting possibilities of veneering and laminating with vacuum without the expense of larger systems or the need for compressed air, yet with the ability to handle a full 4’x 8′ bag.

The heart of the system is an extremely quiet, single chamber 3cfm rocking piston pump, developing 1750 lbs of pressing force per square ft. The adjustable vacuum switch monitors the vacuum level turning the pump on and off as needed.

Compact 300 VacuPress® Pump vacuum pressing bags have heat welded seams and are made from a durable, flexible 30 mil vinyl as well as 30mil polyurethane.

From the C channel bag closure to the quick disconnects, cleanable filter jar and molded bag nipple, the Compact 300 VacuPress® Pump delivers the same engineered quality and performance standards as our professional vacuum pressing line. No detail has been overlooked.

The Compact 300 VacuPress® Pump comes complete and ready to use, no additional parts are required, simply choose a VacuPress® bag to connect to. Since many woodworkers may be trying their hand at veneering for the first time, a comprehensive owner’s manual is included to assist in successful vacuum pressing.

The Total Air VacuPress® Pump, like the Air Powered VacuPress® utilizes a venturi vacuum pump driven by standard compressed air to generate vacuum. Vacuum Pressing Systems uses only “full flow” single stage venturi vacuum pumps for maximum vacuum draw throughout the entire vacuum process. This guarantees short evacuation time and low overall compressed air usage.

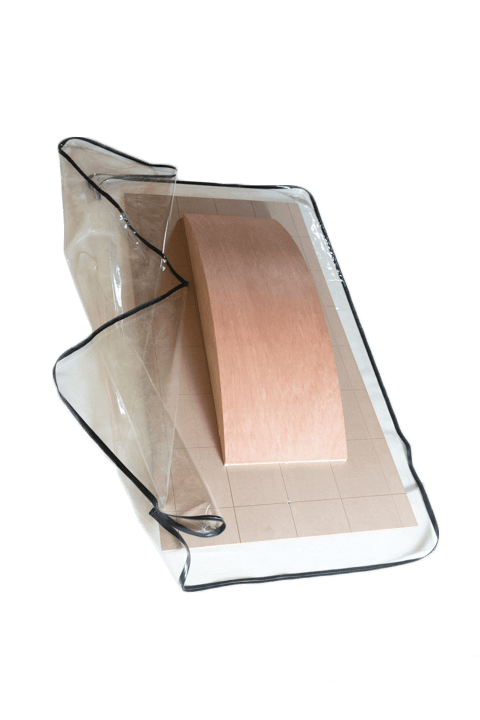

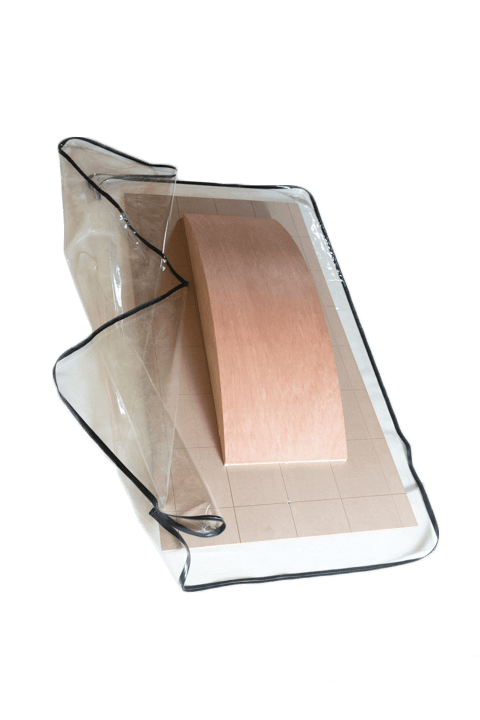

VacuPress® Bags

Extruded Polyurethane is a state-of-the-art water clear vacuum bag material used extensively in high tech industries because it combines high puncture resistance with excellent elasticity, memory retention as well as moderate temperature resistance, up to 150 degrees repeatedly and 180 degrees occasionally. These qualities make extruded polyurethane the perfect material for daily use in the professional shop pressing flat, curved, and shaped work. If you just want the best, this is it.

VacuPress® Fliptop Table Press (Frame System)

When repetition and accessibility are priorities the VacuPress® FlipTop table press is the answer. Designed for quick and easy access, this frame system is ideal for the wood shop which presses flat and low profile curved woodwork more frequently – and can afford dedicated space for the frame system. The VacuPress® FlipTop table press brings a new level of speed and convenience to the vacuum veneering and laminating process.

VacuClamp Vacuum Pods

Arrange the VacuPress® VacuClamp vacuum pods on the work surface, connect the vacuum source, and place your work piece on top. Instantly up to 1800 lbs per sq ft of pressure is applied. One, two, three or more VacuClamp vacuum pods can be connected together. Vertically, horizontally, on any angle, or any combination makes vacuum clamping simple and versatile to use. Because the VacuClamp vacuum pods are only on the underside, access for sanding or machining is unobstructed with no clamping marks.

Parts and Accessories

Our brass bag fitting is designed to mate with the nipple attached to all our vacuum bags. Smooth on the end that goes into the bag nipple and barbed on the other to receive 3/8″ ID hose.

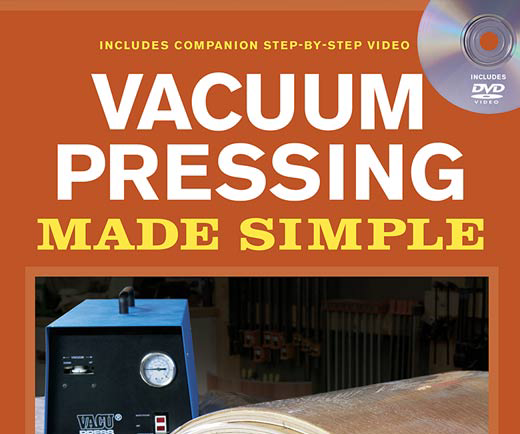

Vacuum Pressing Made Simple (Book/DVD)

Using a vacuum press is the most efficient method of veneering flat and curved panels and making bent laminations, which add decorative options to fine woodwork that can’t otherwise be made using hardwood. Even the smallest of shops can produce high-design wood pieces with the vacuum press because its components can be disassembled and stored in a small space. In this step-by-step book and DVD, Darryl Keil explains and demonstrates how the vacuum press works; how to use it for veneering, wood bending and clamping; how to troubleshoot problems with the press; and how to maintain the equipment for effective, long-term use.

Total running time: 32 min.

Compact 300 Vacupress® Pump (3cfm)

The Compact 300 VacuPress® Pump model is specifically designed for the small or home workshop. The Compact 300 is the perfect choice for woodworkers who want to explore the exciting possibilities of veneering and laminating with vacuum without the expense of larger systems or the need for compressed air, yet with the ability to handle a full 4’x 8′ bag.

The heart of the system is an extremely quiet, single chamber 3cfm rocking piston pump, developing 1750 lbs of pressing force per square ft. The adjustable vacuum switch monitors the vacuum level turning the pump on and off as needed.

Compact 300 VacuPress® Pump vacuum pressing bags have heat welded seams and are made from a durable, flexible 30 mil vinyl as well as 30mil polyurethane.

From the C channel bag closure to the quick disconnects, cleanable filter jar and molded bag nipple, the Compact 300 VacuPress® Pump delivers the same engineered quality and performance standards as our professional vacuum pressing line. No detail has been overlooked.

The Compact 300 VacuPress® Pump comes complete and ready to use, no additional parts are required, simply choose a VacuPress® bag to connect to. Since many woodworkers may be trying their hand at veneering for the first time, a comprehensive owner’s manual is included to assist in successful vacuum pressing.

VacuPress® Bags

Extruded Polyurethane is a state-of-the-art water clear vacuum bag material used extensively in high tech industries because it combines high puncture resistance with excellent elasticity, memory retention as well as moderate temperature resistance, up to 150 degrees repeatedly and 180 degrees occasionally. These qualities make extruded polyurethane the perfect material for daily use in the professional shop pressing flat, curved, and shaped work. If you just want the best, this is it.

VacuPress® Fliptop Table Press (Frame System)

When repetition and accessibility are priorities the VacuPress® FlipTop table press is the answer. Designed for quick and easy access, this frame system is ideal for the wood shop which presses flat and low profile curved woodwork more frequently – and can afford dedicated space for the frame system. The VacuPress® FlipTop table press brings a new level of speed and convenience to the vacuum veneering and laminating process.

VacuClamp Vacuum Pods

Arrange the VacuPress® VacuClamp vacuum pods on the work surface, connect the vacuum source, and place your work piece on top. Instantly up to 1800 lbs per sq ft of pressure is applied. One, two, three or more VacuClamp vacuum pods can be connected together. Vertically, horizontally, on any angle, or any combination makes vacuum clamping simple and versatile to use. Because the VacuClamp vacuum pods are only on the underside, access for sanding or machining is unobstructed with no clamping marks.

Parts and Accessories

Our brass bag fitting is designed to mate with the nipple attached to all our vacuum bags. Smooth on the end that goes into the bag nipple and barbed on the other to receive 3/8″ ID hose.

Vacuum Pressing Made Simple (Book/DVD)

Using a vacuum press is the most efficient method of veneering flat and curved panels and making bent laminations, which add decorative options to fine woodwork that can’t otherwise be made using hardwood. Even the smallest of shops can produce high-design wood pieces with the vacuum press because its components can be disassembled and stored in a small space. In this step-by-step book and DVD, Darryl Keil explains and demonstrates how the vacuum press works; how to use it for veneering, wood bending and clamping; how to troubleshoot problems with the press; and how to maintain the equipment for effective, long-term use.

Total running time: 32 min.