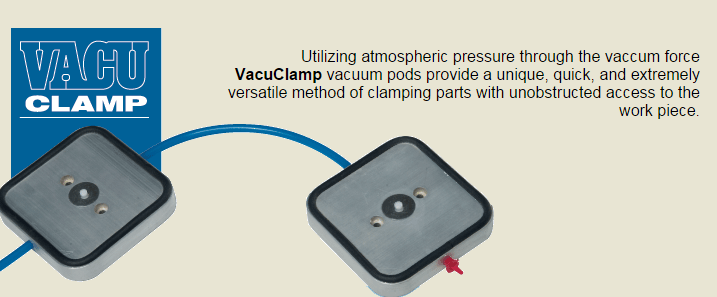

VacuClamp Vacuum Pods

Description

PUMP NOT INCLUDED

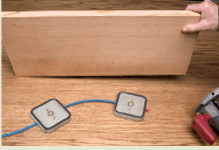

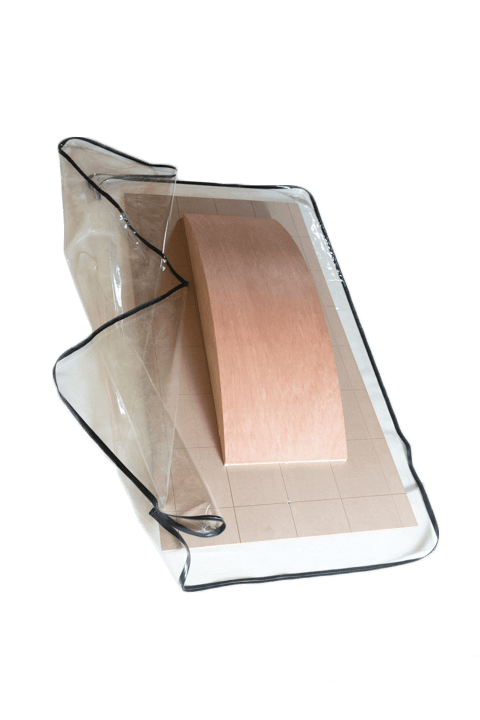

Arrange the VacuPress® VacuClamp vacuum pods on the work surface, connect the vacuum source, and place your work piece on top. Instantly up to 1800 lbs per sq ft of pressure is applied. One, two, three or more VacuClamp vacuum pods can be connected together. Vertically, horizontally, on any angle, or any combination makes vacuum clamping simple and versatile to use. Because the VacuClamp vacuum pods are only on the underside, access for sanding or machining is unobstructed with no clamping marks.

What makes Vacuum Pressing Systems VacuClamp vacuum pods unique is the built in vacuum valve which provides two sided independently controlled clamping. When vacuum is turned on the pods are first drawn down to the work surface for accurate, positive placement. Next, placing the work piece on top engages the vacuum control valve drawing the part to the pod. Each pod is activated individually by the work piece allowing as few or as many pods to be engaged at once. Pods not holding the work piece are still drawn tight to the work surface with no vacuum loss. Pods can also be permanently mounted to the work surface for repetitive operations or vertical clamping. The pneumatic foot switch provides quick release of the work piece by simply stepping down. Release the pedal and clamping force is instantly reapplied.

4″x 4″x 5/8″ Anodized aluminum vacuum pod with spring loaded release valve for independent two sided clamping. Removable plugs for permanent mounting.

1/4″ round neoprene rubber gasket set in a recessed groove for an airtight seal.

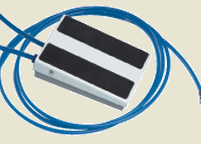

Heavy gauge, powder coated open flow pneumatic foot switch. Depress foot pedal to interrupt vacuum flow.

20′ of vacuum tubing with quick disconnect fitting for use with any VacuPress pump.

2 Pod Clamp Kit Includes:

2 VacuClamp vacuum pods, foot switch and 20′ of vacuum tubing with disconnect fitting.

4 Pod Clamp Kit Includes:

4 VacuClamp vacuum pods, foot switch and 30′ of vacuum tubing with disconnect fitting.