At Yareus Pty Ltd, we supply a wide range of Vac U Press products throughout Australia. In fact, we’re the only company in the country that sells these superior products. We also offer a wide range of laminating and veneering products to meet your woodworking needs, including:

We’ve been in operation for 11 years, providing high-quality machinery and woodwork tools to a wide range of clients.

Imaging the Possibilities with Vacuum Pressing Systems:

Our products are used to create beautiful curved woodworking including:

Woodworking Photo Gallery

- Architectural Millwork

- Fine Furniture

- Musical Instruments

- Cabinetry

- Antique Restoration

- Marquetry

- Spiral Staircases

Vacuum Press Technology – How it works

The principles of vacuum pressing technology are simple. Atmospheric pressure is very heavy; we have over a ton per square foot pressing upon us at sea level. Luckily, we have an equal amount of internal pressure to keep us from being crushed. When the air molecules are removed from a container – even in small amounts – atmospheric pressure immediately becomes evident.

When air is removed from a closed vacuum bag containing a veneering or laminating project, two things happen. First, as the vacuum is created, atmospheric pressure bears down on the work inside the bag with perfect uniformity and enormous pressure. Second, as air is drawn out of the cells in the surface structure of the wood, glue is sucked into these cells. The results are dependable and consistent.

Vacuum Pressing Systems for Laminating & Veneering

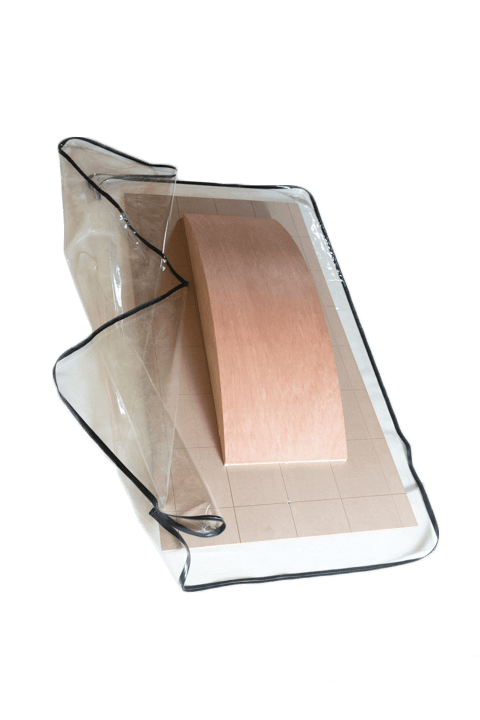

Vacuum Pressing Systems offers two types of veneering and laminating systems. The vacuum pressing “Bag” system which completely envelops the woodwork and the vacuum press table “Frame” system with a hinged lid that drops down over the wood panel being pressed.