VacuPress® Pumps

Compact 150 Vacupress® Pump (1.5cfm)

Description

Compact 150 Vacupress® Pump Specifications and Features:

- 1.5 CFM dual chamber, rocking piston vacuum pump, cool and extremely quiet running, reaching maximum vacuum of 25HG (No compressor needed) Easy access, see- through filter jar with removable bowl for cleaning Vacuum gauge for monitoring the vacuum process Adjustable vacuum switch auto cycles the pump as needed to keep a consistent vacuum level throughout the vacuum process.

- Three position power switch, off, auto cycle and continuous run.

- 10 ft of braided vacuum hose with quick disconnects between the pump and bag

- 25 ft of pressure sensitive neoprene vacuum tape to create a hold down table for routing and sanding parts

- Patch kit for bag repair

- Comprehensive operator’s manual Includes thorough instructions on general veneering, pressing techniques and vacuum clamping.

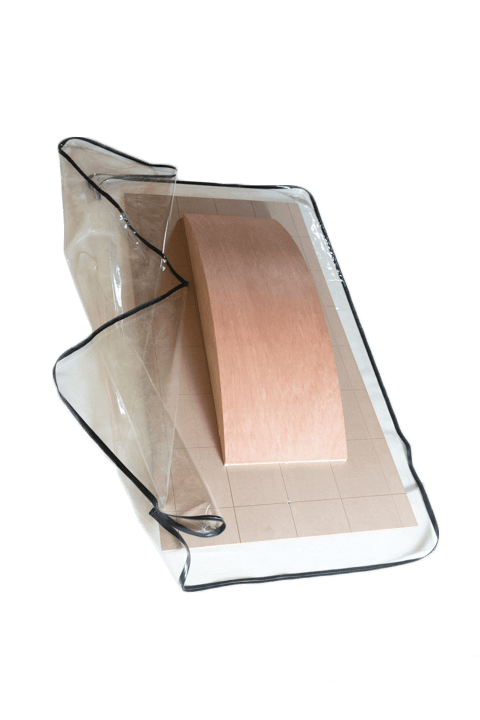

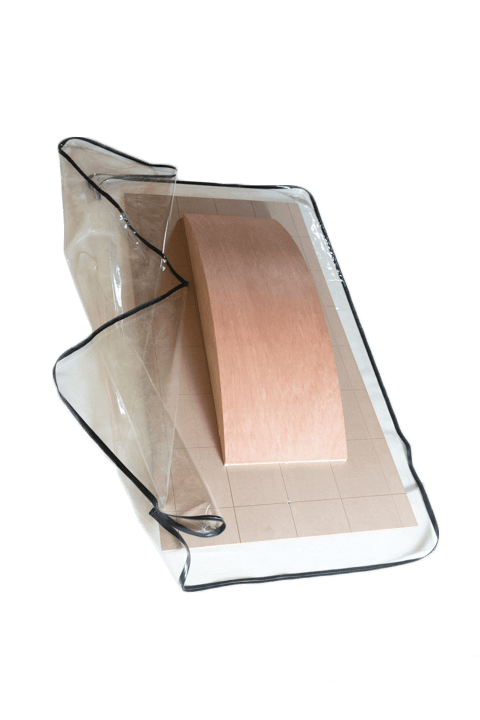

VacuPress® Bags

Extruded Polyurethane is a state-of-the-art water clear vacuum bag material used extensively in high tech industries because it combines high puncture resistance with excellent elasticity, memory retention as well as moderate temperature resistance, up to 150 degrees repeatedly and 180 degrees occasionally. These qualities make extruded polyurethane the perfect material for daily use in the professional shop pressing flat, curved, and shaped work. If you just want the best, this is it.

VacuPress® Fliptop Table Press (Frame System)

When repetition and accessibility are priorities the VacuPress® FlipTop table press is the answer. Designed for quick and easy access, this frame system is ideal for the wood shop which presses flat and low profile curved woodwork more frequently – and can afford dedicated space for the frame system. The VacuPress® FlipTop table press brings a new level of speed and convenience to the vacuum veneering and laminating process.

VacuClamp Vacuum Pods

Arrange the VacuPress® VacuClamp vacuum pods on the work surface, connect the vacuum source, and place your work piece on top. Instantly up to 1800 lbs per sq ft of pressure is applied. One, two, three or more VacuClamp vacuum pods can be connected together. Vertically, horizontally, on any angle, or any combination makes vacuum clamping simple and versatile to use. Because the VacuClamp vacuum pods are only on the underside, access for sanding or machining is unobstructed with no clamping marks.

Parts and Accessories

Our brass bag fitting is designed to mate with the nipple attached to all our vacuum bags. Smooth on the end that goes into the bag nipple and barbed on the other to receive 3/8″ ID hose.

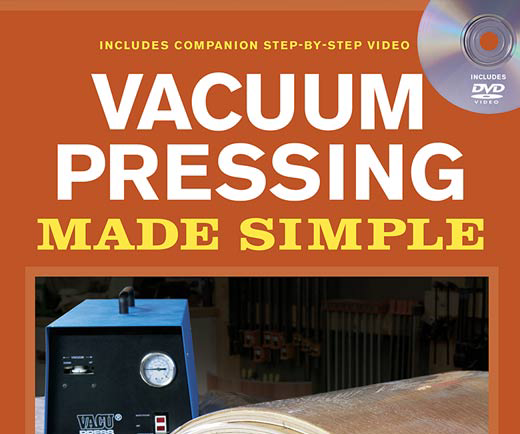

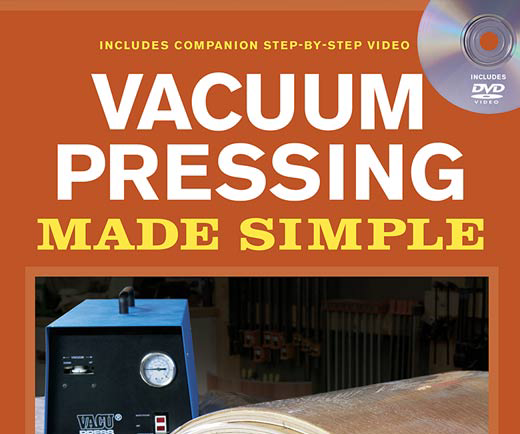

Vacuum Pressing Made Simple (Book/DVD)

Using a vacuum press is the most efficient method of veneering flat and curved panels and making bent laminations, which add decorative options to fine woodwork that can’t otherwise be made using hardwood. Even the smallest of shops can produce high-design wood pieces with the vacuum press because its components can be disassembled and stored in a small space. In this step-by-step book and DVD, Darryl Keil explains and demonstrates how the vacuum press works; how to use it for veneering, wood bending and clamping; how to troubleshoot problems with the press; and how to maintain the equipment for effective, long-term use.

Total running time: 32 min.

VacuPress® Bags

Extruded Polyurethane is a state-of-the-art water clear vacuum bag material used extensively in high tech industries because it combines high puncture resistance with excellent elasticity, memory retention as well as moderate temperature resistance, up to 150 degrees repeatedly and 180 degrees occasionally. These qualities make extruded polyurethane the perfect material for daily use in the professional shop pressing flat, curved, and shaped work. If you just want the best, this is it.

VacuPress® Fliptop Table Press (Frame System)

When repetition and accessibility are priorities the VacuPress® FlipTop table press is the answer. Designed for quick and easy access, this frame system is ideal for the wood shop which presses flat and low profile curved woodwork more frequently – and can afford dedicated space for the frame system. The VacuPress® FlipTop table press brings a new level of speed and convenience to the vacuum veneering and laminating process.

VacuClamp Vacuum Pods

Arrange the VacuPress® VacuClamp vacuum pods on the work surface, connect the vacuum source, and place your work piece on top. Instantly up to 1800 lbs per sq ft of pressure is applied. One, two, three or more VacuClamp vacuum pods can be connected together. Vertically, horizontally, on any angle, or any combination makes vacuum clamping simple and versatile to use. Because the VacuClamp vacuum pods are only on the underside, access for sanding or machining is unobstructed with no clamping marks.

Parts and Accessories

Our brass bag fitting is designed to mate with the nipple attached to all our vacuum bags. Smooth on the end that goes into the bag nipple and barbed on the other to receive 3/8″ ID hose.

Vacuum Pressing Made Simple (Book/DVD)

Using a vacuum press is the most efficient method of veneering flat and curved panels and making bent laminations, which add decorative options to fine woodwork that can’t otherwise be made using hardwood. Even the smallest of shops can produce high-design wood pieces with the vacuum press because its components can be disassembled and stored in a small space. In this step-by-step book and DVD, Darryl Keil explains and demonstrates how the vacuum press works; how to use it for veneering, wood bending and clamping; how to troubleshoot problems with the press; and how to maintain the equipment for effective, long-term use.

Total running time: 32 min.